product features

At Northwest Door & Sash Company, we strive to perfect our craft of impeccably constructed windows & doors. Our extensive and unique experience in this field is immediately apparent by our finished products.

The time-tested construction techniques, material choices, finishes and hardware selection are all the result of a long-standing dedication to design, function, thoroughness and high attention to detail.

There are scores of companies that manufacture windows & doors, many of which claim to produce superior products. Northwest Door & Sash Co. runs far ahead of the pack, producing only the best handcrafted, solid wood windows and doors.

Below are some of the features that make our windows & doors uniquely superior:

pocket mortise & tenon joinery

Widely held as the strongest and longest-lasting wood joinery technique, the mortise & tenon’s benefit over dowel joints is the higher surface area for glueing. It requires more precision, material and time to perform than other wood joints and thus has been abandoned by almost all in the industry. It is the cornerstone of all of our sash and doors, giving the highest degree of integrity and longetivity to our doors and windows.

true divided lites

One of the foundations of our company is providing True Divided Lites. Most other window and door manufacturers have opted for Simulated Divided Lites (SDL) in order to produce a less expensive product. However, if there is glass failure or breakage on an SDL, the entire sash must be removed, discarded and replaced – a very difficult, expensive and wasteful operation. To the contrary, True Divided Lites allow a single piece of glass to be replaced quite readily, without disturbing the surrounding door, sash or entire installation. Our products can be maintained and repaired easily and inexpensively.

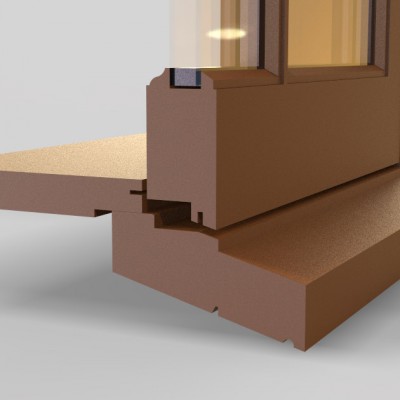

one-piece sills

Window and door sills are the hardest hit by weather. It takes more time and effort to create solid, one-piece sills but by not having a joint that water can get into, they are superior to sills that are segmented.

splined contraction joints

Exterior wood doors typically show the most weather problems at the bottom rail. As the relatively wide (approx. 8″ to 12″) bottom rail expands and contracts seasonally, it can crack, particularly if it was dowelled or uses veneers, as is the case in most U.S. production methods. We prevent against this by adopting the the European method of incorporating a slip joint in the middle of the bottom rail, insuring that the rails can expand and contract without splitting.

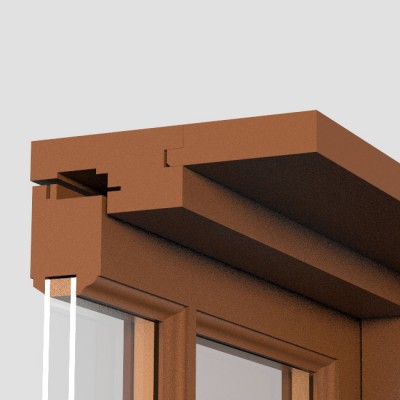

coped glass stops

Unlike mitered joints that notoriously open up after as little as one year’s weather cycle and wood movement, coped joints remain tightly closed. Our horizontal pieces run under the verticals, forming a sloped mini-sill. This creates a very water-resistant corner joint, maximizing the longevity of the insulated glass unit. Additionally, by glazing to the exterior, the interior is kept pristine, free of nail holes and mitered corners.

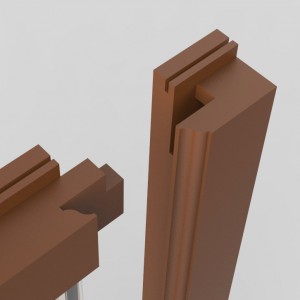

jamb extenders

Our Doors and Windows come with pre-glued heavy, straight and strong jamb extenders that are precision fit into the base jambs. They are made in our shop to the exact overall jamb width desired. All of this saves time at installation and insures a stiff, straight jamb that finish carpenters can’t say enough about. An added benefit to the increased thickness of our jamb extenders is the ability for interior and exterior casings to be attached more securely.

solid wood construction

Most of our competitors have moved to “engineered” door components (stiles and rails), purportedly for the added stability. Through our vast experience, however, we have found that engineered stiles have a greater rate of failure (veneer splitting or delaminating) than does solid, high quality, quarter-sawn wood. This is particularly true at door bottom rails, and especially so if the species is VG Douglas Fir, solid mahogany or Accoya, all of which we use regularly.

sanding & edge detail treatment

Our philosophy is that doors and windows are the built-in “furniture” of a house. With this constantly in mind, we strive to make truly furniture-quality products. Thus, our level of sanding and edge detail treatment goes well beyond what is typically found in the industry. This distinguishes our doors and windows and is readily apparent to the critical eye.